Outdoor 3 Phase Oil Cooling Power Transformer

Product features

1. It’s an environment-friendly transformer with low no-load loss, no-load current and noise.

2. No oil storage box to save space.

3. Whole sealed with vacuum oil filling, high stability of insulation.

4. Adopts the corrugations on the oil tank as its heat-radiation parts, corrugations can expand or contract accord to the change of oil volume.

5. Fully sealed structure, maintenance free.

6. With oil level gauge to ensure the safety running.

Applicable Environment

1.High ambient temperature: +40℃

2.Low ambient temperature: -25℃

3. Altitude: <1000m

4. Monthly average relative humidity: 90% (20℃)

5. Installation location: Install in a place where there is no fire, explosion hazard, serious pollution, chemical corrosion and severe vibration, indoors or outdoors.

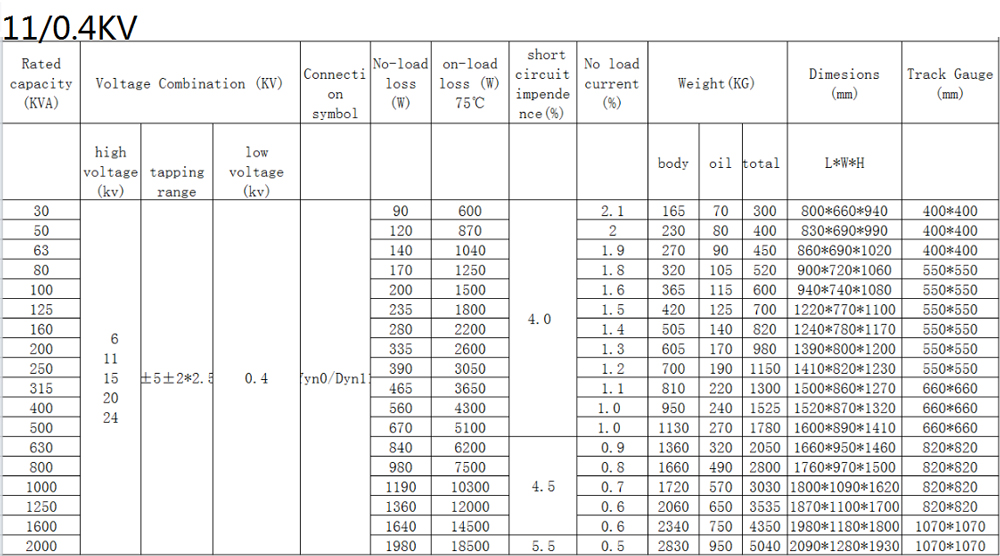

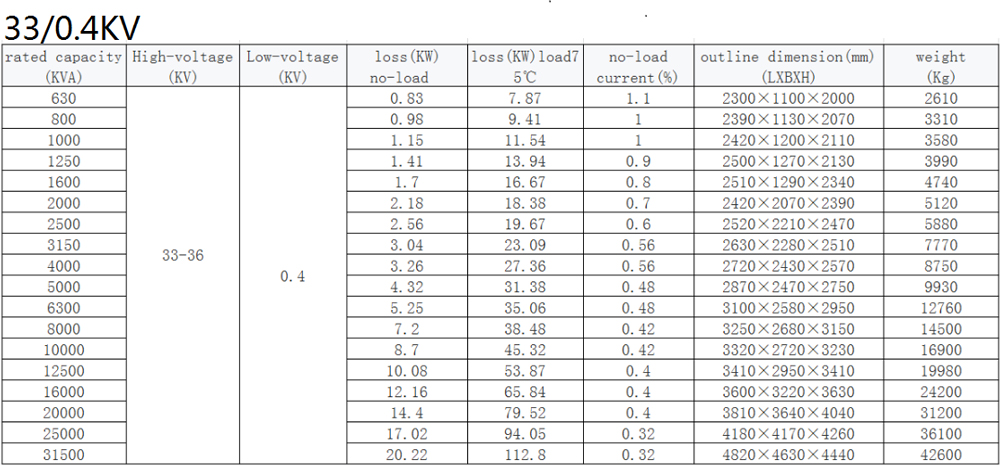

Product technical parameters

Structural features

| Reliable structure |

| Depending on mature technologies, we made a lot of improvements on the basis of traditional structure:Spiral winding with longitudinal oil duct that enjoys good inner heat dissipation;Effective support at winding end surface that further improve the short-circuit resistant capacity of winding;

Adoption of new hoisting structure and body positioning structure that guarantee safety in long-distance transport and in service; More unique and reliable structure for your option; Adoption of transformers with more excellent performance to improve the technical content. |

| Excellent materials |

| Because we use oxygen-free copper wires of lower resistivity, which will become smoother and burr-free after a series of surface treatment, so the load of our transformer is lower and the electric performance is better.We use high quality silicon-steal sheets which are of lower specific loss, so the no-load loss of the transformers is lower.We use high quality wooden laminating insulation pieces, which won’t split or move even under the influence of short circuit current.

We use thoroughly filtrated transformer oil containing less water, gas or impurities, which makes our transformer work better. We use high quality rubber sealing material, which can prevent the transformers from aging or leakage effectively. All raw materials have passed the quality testing, and all the raw factories have passed the national standard ISO9000 inspection. |

| Good technology and economic performance |

| Improved from S9 series product, S11 series product reduces the no-load loss by 31%; no-load current by 75-90%; average temperature-rise level by 3-5 db; and double the products’ service life. Even under 20% overloads, it can also work for a long period of time. |

| Hermetically sealed |

| The “M” in S11 (M) stands for omniseal structure that the oil tank employed. Compared with common oil-immersed transformer, omniseal oil-immersed transformer discards the oil conservator but adopts wing-likes corrugation for replacing oil tube as component of heat dispersion. The corrugated oil tank which is made of high-quality cold-rolled sheets is produced on the special production lines. The wing-like corrugation will expand and compress as that volume of transformer dose, so that the transformer is separated of operation and atmosphere and can prevent or slower deterioration of oil and breathing of insulation. All these ensure the reliability of operation and without maintenance.After the treatment of dealing, derusting and parkerizing, the surface of corrugated oil tank is coated with paint which provides three-proofing function, it is suitable for the use in the environment such as metallurgy, petrochemical industry and mining, etc. |

Packing&Shipping